Introduction video

What Are the Advantages of the Durma TP Hydraulic Punch Press?

TP Hydraulic Punch Presses are excellent for small, medium and large format sheet processing. They are equipped with punching, forming, tapping, and wheel technology capabilities. They have a Stress relieved O frame. Their flexible turret configurations eliminate tool setups. They have one of the best controllers the market has to offer. They offer powerful control with user friendly CAD-CAM Software. Moreover, they have auto lubrication of moving parts, which will save you time and manpower.

Programmable sheet clamping system decreases set-up times and scrap ratio. Automation can be easily integrated for efficient and lean operations while also Increasing operator safety and decreasing operator fatigue.

The punching head stroke rates of 1200 strokes per minute during punching and 3200 per minute during marking. Also, it can be formed at punching speed. The machine control adjusts stroke travel speed and position.

With its dynamic design, it is possible to obtain speeds of 116 m/min in X axis, 80 m/min in Y axis and 140 m/min simultaneously. Moreover, high acceleration (1,5 g) is possible across the whole working range without any restriction.

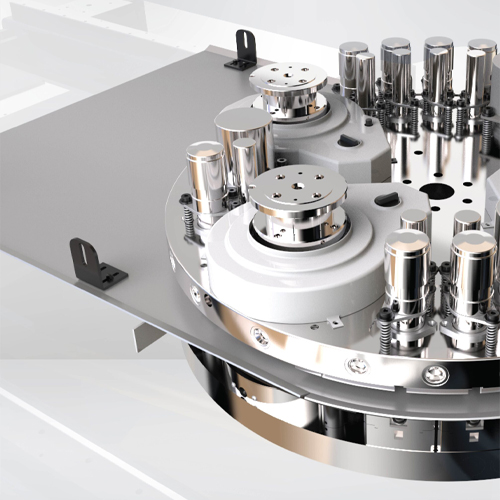

Technology of the Durma TP Hydraulic Punch Press

TP Hydraulic Punch Press technology is designed to allow perfect and high-quality drilling operations. Durma TP Punch Presses are developed with high-tech standards and offer you exact solutions.

TP Hydraulic Punch Press has an efficient design and a strong body for perfect machining. These presses represent the combination of economy and excellent process performance.

TP Hydraulic Punch Press adds value to your business by offering solutions suitable for your needs with standard and optional equipment options. With its high technology features, high impact, high precision and high-performance criteria, TP Hydraulic Punch Press is user friendly.