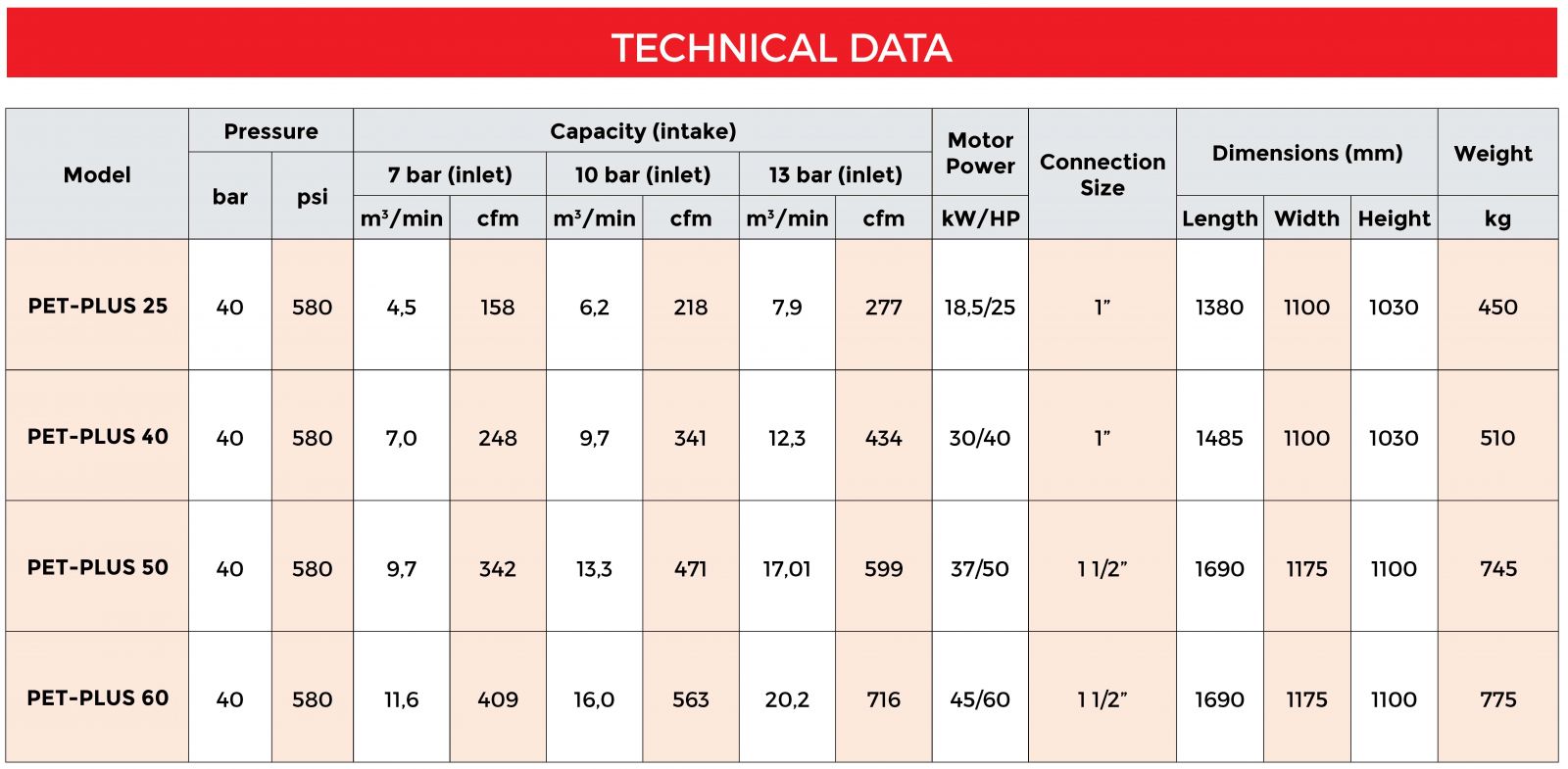

MODELS AND TECHNICAL INFORMATION

GENERAL INFORMATİON

WHY BOOSTER COMPRESSOR?

Compressed air (pneumatic energy) for the manufacturing sector is as important an energy source as electricity and hydraulics. Especially in the production of pet bottles which are becoming increasingly widespread nowadays, high pressure air is a necessity in applications such as drive cylinders, presses and fixing apparatuses, in sealing tests in pneumatic and hydraulic devices. Unlike other applications where pressure air is required, in these applications both low pressure and high pressure air reaching 40 bar are used at the same time in enterprises. Therefore, instead of designing the whole pressurized air system according to the high pressure, it is the most suitable solution to increase the air pressure only at high pressure points.

COMPRESSOR BLOUSE

- Cast iron castings with high strength suitable for heavy working conditions; An oil level indicator, a blowdown valve and oil fill / drain tapes positioned so easily visible on the sump.

- Cooling fin cast iron cylinders and special aluminum alloy top heads help the system operate at lower temperatures.

- The spheroidal casting crankshafts and counterweights, provided with dynamic balance, precise production processes, provide long service life.

- Special alloyed aluminum pistons and connecting rods provide less heat to the crankshaft with less heat, as well as less pressure on the crankshaft.

- Specially designed high-speed concentric valves made from stainless steel in grade 1 provide high air flow capacity, while concentric valves specially designed for high pressure conditions in stage 2 and 3 ensure maximum headroom temperatures at maximum level by keeping airflow at maximum level.

- Compression and oil rings help to keep the airflow at maximum level and prevent oil passage.

HOME MOTOR AND DRIVE SYSTEM

- As a standard in PET-PLUS series compressors, high efficiency IE2 efficiency class IP55 motors are used.

- The drive of the crankshaft is directly coupled with the flexible coupling between the compressor block and the main motor.

- The special unloading system extends the life of the electric motor and the compressor block.

COOLING AND LUBRICATION SYSTEMS

- In order to provide effective cooling in the system, aluminum combi radiators are used in four stages (one for oil cycle, three for each compression stage air) that can reduce compressed air to ambient temperatures.

- Only the air guide plate on which the cylinders and top heads are left open, and the deep cooling fins on the cylinders are provided to cool the compressor block in a level that ensures that the compressor operates without stop.

- Instead of the lubrication lubrication system, the preferred main engine shaft is directly supported by a hydraulic oil pump to effectively cool the compressor block by turning over the hot parts such as the connecting rod and the crankshaft.

ELECTRIC SYSTEM

- PLC based control and system monitoring with digital display panel

- Flexible operation with up to 100 user parameters such as motor switching, inlet-outlet air pressure and temperature, minimum operating pressure, minimum oil pressure and maximum operating temperature

- Monitoring of maintenance intervals with 5 different predefined counter structures

- Reliable operation with reduced number of mechanical control equipment such as relays and contactors

- Remote control possibility with optional GPRS modüle

- Control of up to 8 compressors at the same time with optional co-aging.

STANDARD FEATURES

- Piston compressor block

- 380V / 3phase / 50Hz IE2 efficiency class IP55 main motor

- Automatic evacuation system for unloading

- Direct coupling drive system with flexible coupling

- Long life bearings

- Four-stage aluminum combi boiler radiator

- Air intake filter and silencer for idle function

- Oil pump lubrication system

- Oil level indicator

- Special evacuation system to prevent oil blasting

OPTIONS

- Oil heater

- GPRS module for remote control

- Multi-compressor control mechanism with coarse aging

- IE3 efficiency class main engine

- Other input voltage options except 380V / 3phase / 50Hz