Product Feature

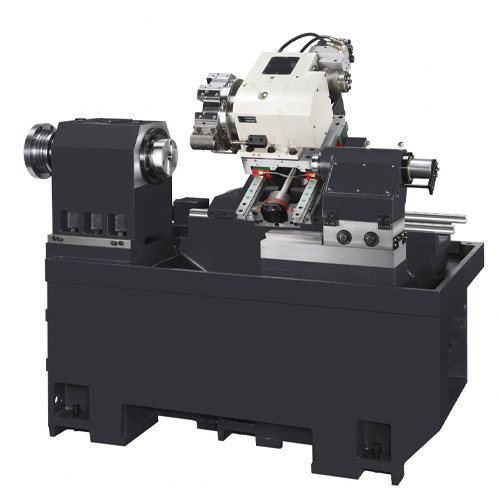

30˚ slant wedge saddle design and heavy-duty structure foundation, an optimization of the rigidity of the overall machine structure is applied to the headstock, turret, and tailstock. KFM insists to use MIT (Made In Taiwan) casting only to offer our users the best quality assurance. Lasting metal cutting precision accuracy and cutting tool life extension are highly guaranteed.

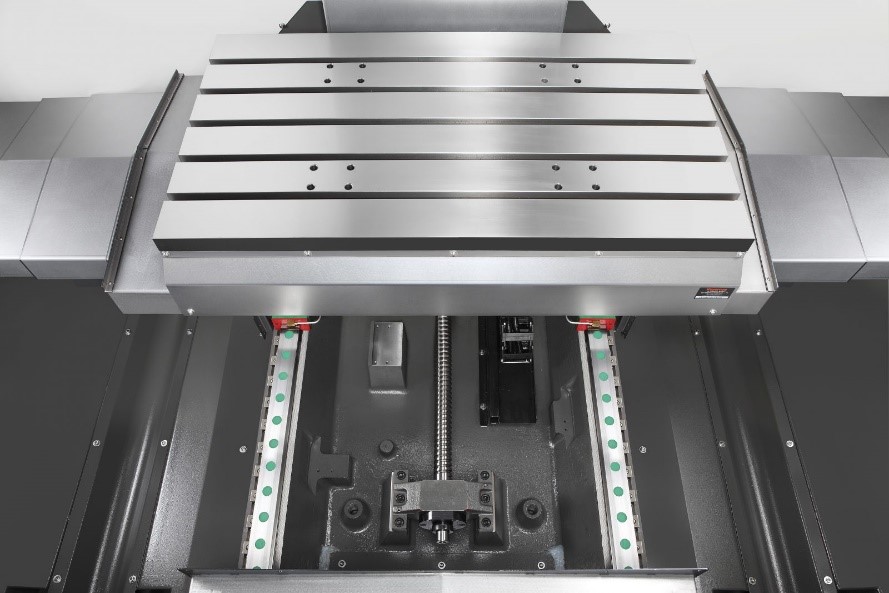

Linear slideway lowers the friction and provides high positioning accuracy. In the aspect of after-sales maintenance, linear guide way is relatively maintenance-friendly by just changing the sliding blocks and sideways will be able to regain the performance display.

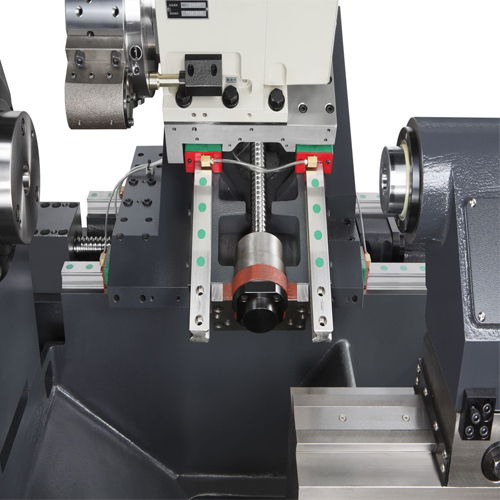

Ball Screw

All products are equipped with C3 class ball screws to ensure high positioning accuracy. The ball screw pretension design is applied to all axes to effectively minimize the backlash compensation of the machine body needed. The repeatability and positioning accuracy is highly secured.

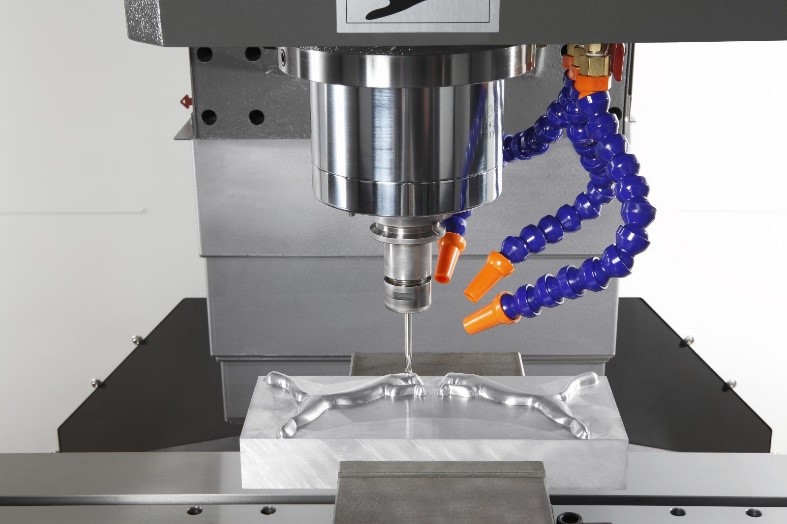

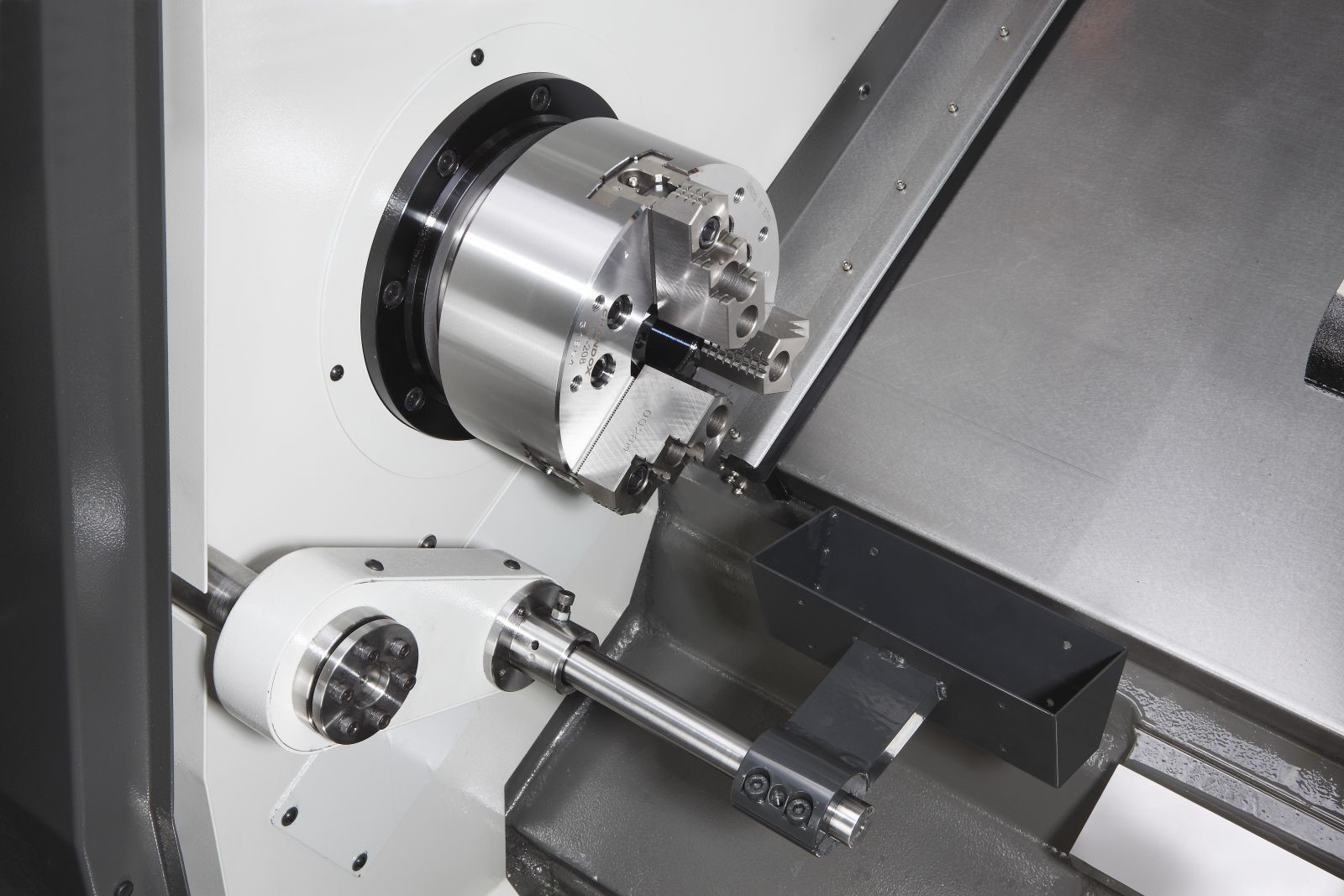

Spindle

The headstocks for all the products are equipped with one-piece casting. High precision Japan-made bearings from NSK are installed to provide high capacity of the bearing load, and effectively deliver a high precision and durability performance.

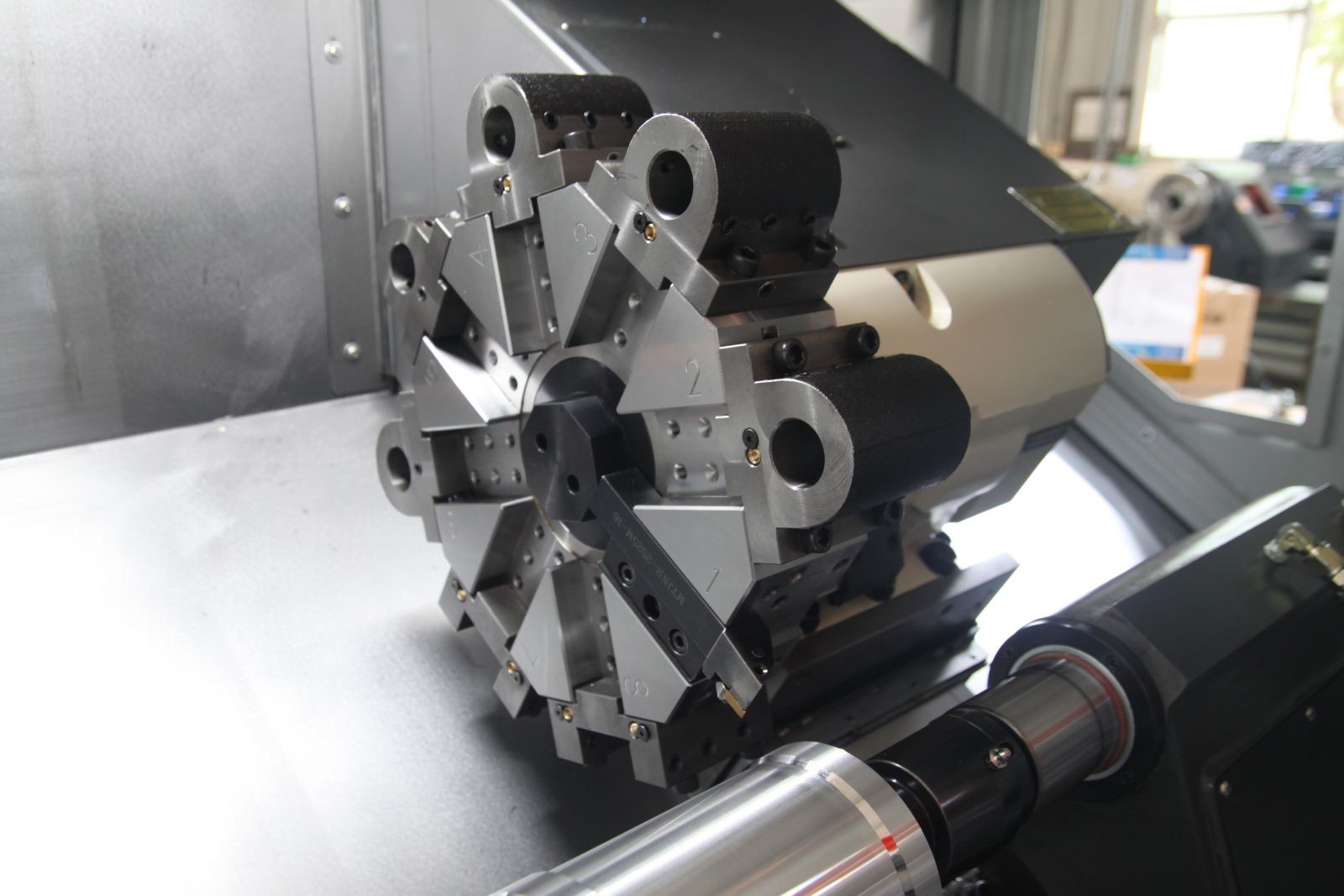

Turret

The interior mechanism employs flat parallel cam, featuring high indexing accuracy and fast tool changing time. Turret disk rotation is driven by oil pressure motor to provide strong cutting torque and enhance the performance stability. It suits both heavy and light cutting.

Specifications

| ITEM | UNIT | KT-16 |

| Controller | - | Fanuc 0i-TF Plus |

| - | Mitsubishi M80A | |

| - | Siemens 828D | |

| Maximum turning diameter | mm | 260/240 |

| Saddle swing diameter | mm | 280 |

| Bed swing diameter | mm | 450 |

| Maximum turning length | mm | 300 |

| Bar capacity | mm | 42 |

| Power chuck diameter | inch | 6 |

| Spindle motor power | kw | 7.5/11 |

| Spindle speed | rpm | 5,000 |

| Spindle nose taper | ASA | A2-5 |

| Spindle bearing diameter | mm | 90 |

| Spindle taper | - | 1/20 |

| X-axis travel | mm | 125+20 |

| Z-axis travel | mm | 300 |

| X-axis rapid feed rate | m/min | 24 |

| Z-axis rapid feed rate | m/min | 30 |

| Guide way type | sideway | Linear |

| Turret driven type | - | Hydraulic |

| Tool capacity | station | 8/10 |

| OD tool shank size | mm | 25 |

| ID tool shank size | mm | 32 |

| Tailstock travel positioning | - | Manual |

| Tailstock quill travel | mm | 80 |

| Tailstock travel | mm | 200 |

| Quill taper size | MT | MT#4 |

| Quill taper diameter | mm | 70 |

| Floor space (LxWxH) | mm | 2978x1610x1772 |

| Machine weight | kg | 3300 |

Spindle

The headstocks for all the products are equipped with one-piece casting. High precision Japan-made bearings from NSK are installed to provide high capacity of the bearing load, and effectively deliver a high precision and durability performance.

Spindle Motor Power

Turret

The interior mechanism employs flat parallel cam, featuring high indexing accuracy and fast tool changing time. Turret disk rotation is driven by oil pressure motor to provide strong cutting torque and enhance the performance stability. It suits both heavy and light cutting.

|

|

| Item/ToolCapacity | Unit | 8T | 10T | 12T |

| Center height | mm | 120 | 120 | 120 |

| Rotating time (tool to tool) | sec | 0.4 | 0.4 | 0.4 |

| Rotating time (locking included) | sec | 0.5 | 0.5 | 0.5 |

| Tool indexing time | sec | 1.2 | 1.4 | 1.5 |

| Tool inddexing time (locking included) | sec | 1.4 | 1.6 | 1.7 |

| Oil hydraulic motor type | - | OMP 80/100 | OMP 80/100 | OMP 80/100 |

| Repeated accuracy | mm | 0.003 | 0.003 | 0.003 |

More

Bar Feeder

Optional automatic bar feeder choice will provide better productivity performance by minimize the time needed for feeding the materials. No restriction on the spindle speed or the shape of material. Alternative feeding torques can be applied for different diameters of material, weight and length to avoid the deformation of materials.

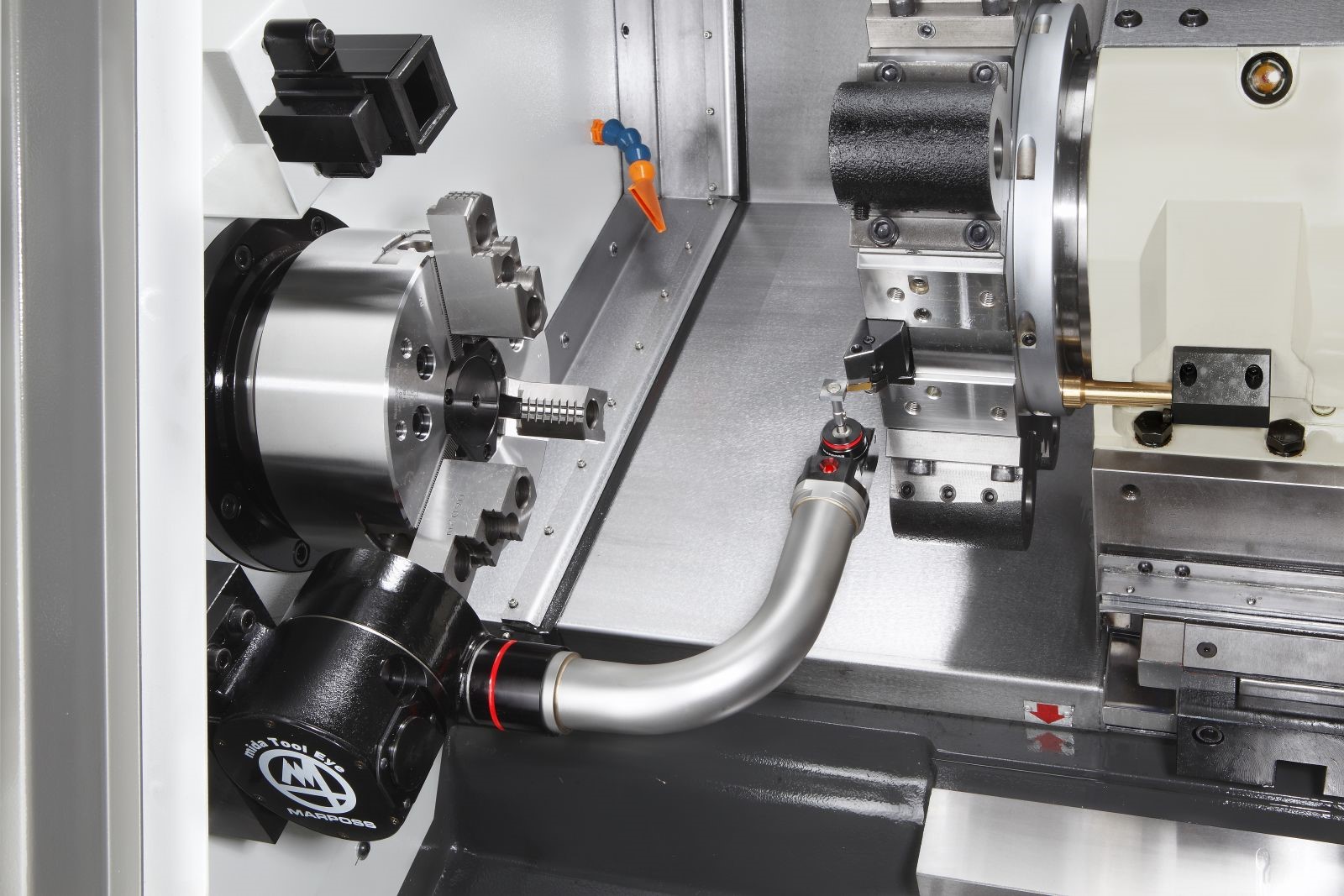

Tool Presetter

Optional Reinshaw or Marposs tool presetter accessory provides higher production output and minimizes the machine idle time. It precisely measures the cutting tool length and diameter, and offers solution for tool setting, broken tool detection, component set-up, in-cycle gauging and first of component inspection, with automatic offset updates.

Parts Catcher

Parts catcher automatically receives the finished parts. To provide easy access to the finished parts without going through the trouble of opening the machine door. High efficiency and operator friendl

Gantry Loading / Unloading System

Automatic parts loading and unloading system provides one more solution to the high labor mobility issue with the side benefit of offering high production output. The system is available to one-to-one or one-to-many machines. This is a future tend that you wont want to miss!