Introduction video

MODELS AND TECHNICAL INFORMATION

GENERAL INFORMATION

EASY USE

INVERSYS PLUS series screw air compressors have been produced in order to work successfully in different application areas. High performance and quality parts used in the manufacture and assembly of products designed to be easily adaptable and user-friendly at every level provide long maintenance intervals and consequently low operating costs.

AFTER SALES SUPPORT SERVICE

DALGAKIRAN operates in more than 130 countries worldwide and has more than 100 authorized dealers in Turkey.

SCREW BLOCKS

- New generation of screw blocks, designed with the benefit of the latest technology such as "Computational Fluid Dynamics (CFD)" and "Finite Element Method (FEM)" and manufactured with advanced manufacturing techniques, new rotor profile and lobe combination provide high efficiency, It offers consumption.

- There is a new generation of ball bearing tilt system with 3 times more load carrying capacity than standard designs.

- With the optimal lobe combination, the new rotor profile allows less air escape and reduces torque requirements, resulting in a significant reduction in energy costs.

MAIN MOTOR AND DRIVE SYSTEM

- In the INVERSYS PLUS series high efficiency and high speed, IE3 energy class, IP55 engines suitable for driving with inverter are used as standard.

- Unlike star-triangle and soft-starter motor drive methods, low-energy loss and high performance inverter equipments provide a significant energy savings as well as avoiding unnecessary stop-and-start wear of the motor by adjusting the motor speed according to the desired flow capacity.

- The drive of the screw rotor shaft takes place directly between the screw block and the main motor with a flexible coupling with 1: 1 transmission.

- Unlike other power transmission systems, mechanical losses are reduced to the minimum level by means of a direct coupling transfer system to save energy.

- By not using the belt-pulley mechanism, noise and vibration levels are noticeably reduced.

AIR SUCTION SYSTEM

- FEM and "Fluid Dynamics".

- The simple design of the suction regulator, which consists of three control block units, a solenoid valve and a control cylinder, ensures that periodic maintenance is easy.

- Suction regulator provides reliable working performance up to 8000 hours with the use of first class materials in manufacturing, reduced number of gaskets in design.

- The suction valve promises low pressure drops and high performance with a fully upright position, almost straight and unidirectional air flow, a new profile design and a 25% increase in air exit area when the suction valve is open.

- The two-stage air intake filter system, consisting of a replaceable microfiber glass front panel filter and cassette-type air inlet filter with interchangeable paper elements, minimizes problems that may occur in dusty environments by providing fresh air for the screw block and cooling system.

AIR / OIL SEPARATOR

- It achieves a more efficient decomposition at a lower volume with deep-bedded separating layers.

- It has a performance design that provides 3-step decomposition.

- After separation, a low oil solubility of 3 mg / m3 is obtained.

COOLING SYSTEM

- The aluminum combi cooler with long-lasting Bar / Plate system guarantees trouble-free operation in all kinds of conditions.

- The four-way thermostatic valve prevents water condensation at low temperatures, extending oil life and eliminating risk of failure.

- The new wing profiles are supported by quiet and efficient axial fans driven by a main motor independent electric motor.

- It has new fan nests which are easy to clean and provide service in a short time.

- With variable speed control fans, independent of the main motors, effective cooling is ensured so that the compressor is kept at the optimum working temperature, thus compressing the air with high performance and efficiency. (Except INVERSYS + 5P-22P and water-cooled models)

SAFETY AND WARNING SYSTEMS

- Main motor and fan motor overcurrent control

- Phase sequence, deficiency and imbalance control

- Main motor temperature control with PTC

- Screw extreme temperature control system

- High pressure control system

- Separator pollution warning system

- Air filtration pollution warning system

- High pressure relief valve

- Separator tank safety valve

- Emergency stop button

- Service warning system

ELECTRICAL SYSTEM

- It has an LCD control panel that shows the operation and service functions in a way that everyone can easily understand.

- Mechanical safety systems are supported by PLC controlled safety switches and relays.

- In electric panel design, brands which offer quality products in world standards have been preferred.

CANOPY DESIGN

- Canopy design requiring minimum working area

- Ergonomic design that provides ease of maintenance and allows easy intervention at every point of the machine

- Service closures that can be easily removed

- Vibration chocks made of special rubber that eliminate vibration and the problems it may cause

- Stainless and puncture resistant electrostatic powder paint

- Non-flammable canopy cover minimizing sound level

STANDARD FEATURES

- Highly efficient screw block

- 380V / 3 phase / 50Hz high speed IE2 energy class inverter compatible IP55 main motor

- Inverter suitable for heavy working conditions

- Direct coupling drive system with flexible coupling

- Variable speed (VSD) fan (except INVERSYS + 5P-18P and water cooled models)

- Detachable acoustic canopy

- Rigid chassis base

- Micro glass fiber pre-filter with EU3 norm

- Air / oil separator and tank providing maximum oil solubility of 3 mg / m3

- Dry-type air filtration at 3 micron resolution

- Full flow oil filtration at 10 micron resolution

- Electropneumatic charge-empty suction valve

- Minimum pressure valve

- Thermostatic valve

- Quick relief valve and silencer

- LCD panel PLC control unit

- 4000 hours working life with factory-filled oil

OPTIONS

- Water cooling system

- Air + water (Hybrid) cooling system with heat recovery

- Oil heater

- Water separator with automatic drainage system

- Other input voltage options except 380V / 3phase / 50Hz

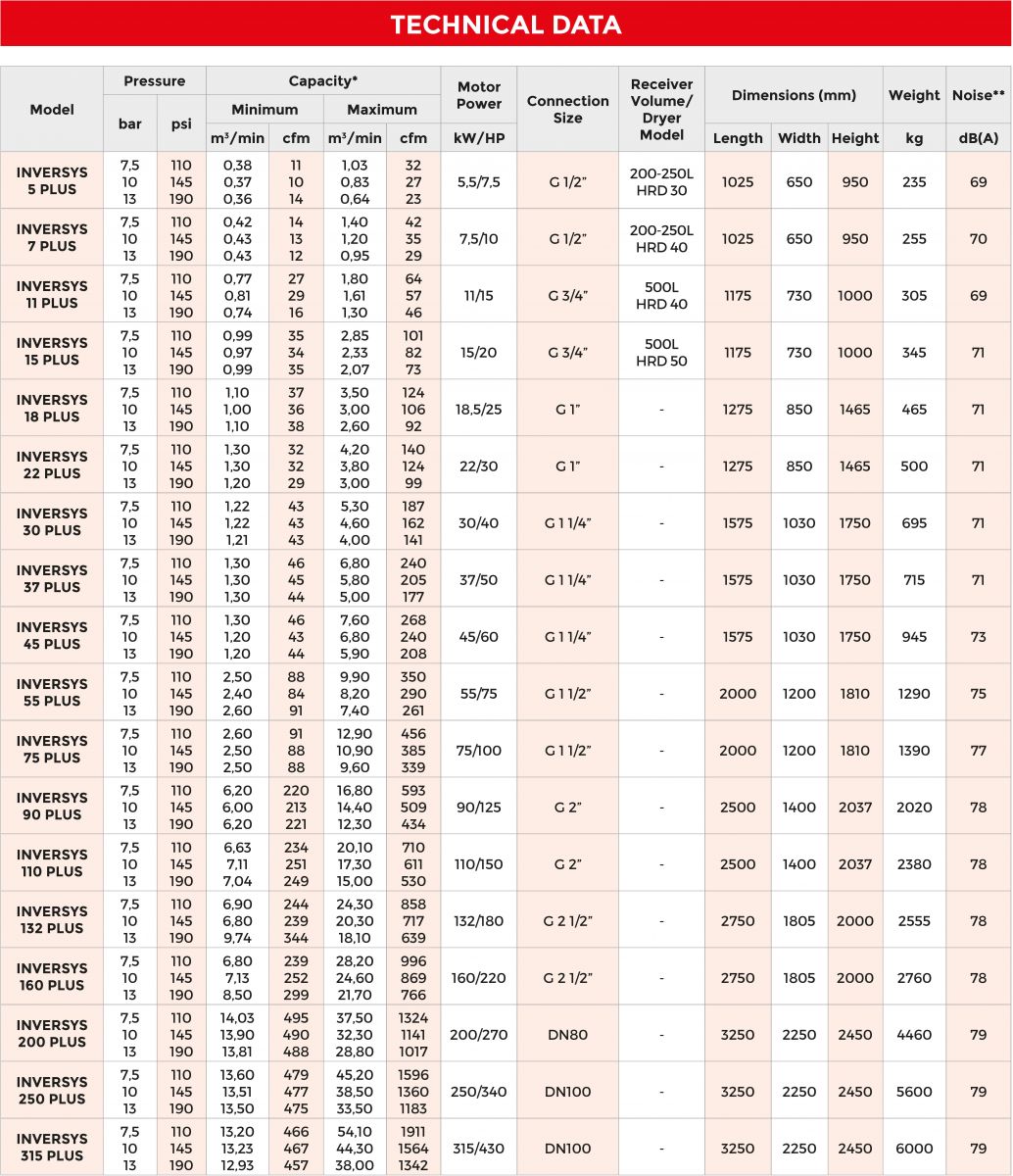

- Unit performances measured in reference conditions which are 1 bar absolute air Pressure, %0 relative humidity, 20°C inlet air temperature, 71°C thermostatic valve set temperature and use of Smartoil.

- DALGAKIRAN compressors reserves its rights to make changes in its products and specifications without prior notice.

* Refers to free air delivery measured according to ISO 1217:2009, Annex E standard.

** Refers to sound Pressure level measured according to ISO 2151:2004 and ISO 9614/2 with ± 3 dB(A) tolerance.