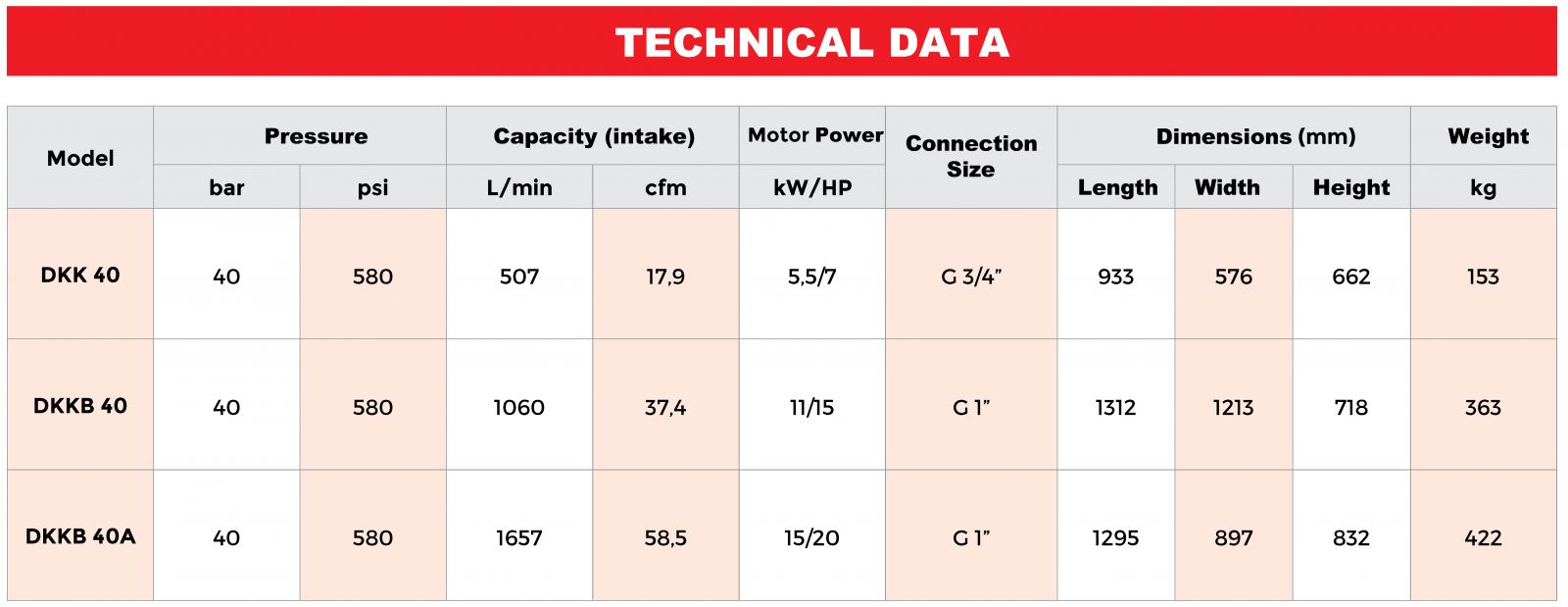

MODELS AND TECHNICAL INFORMATION

GENERAL INFORMATİON

Long Life

Cast iron castors and cylinders, pistons operated at low speeds, corrosion and heat resistant stainless steel valves, cooling finned cylinders and top heads, DALGAKIRAN DKK series ensure long life of high pressure piston air compressors.

Easy To Use

The DKK series is produced with high pressure piston air compressors to work successfully in different application areas. High performance and quality parts used in the manufacture and assembly of products designed to be easily adaptable and user-friendly at every level provide long maintenance intervals and consequently low operating costs.

After Sales Support Service

DALGAKIRAN operates in more than 130 countries worldwide and has more than 100 authorized dealers in Turkey.

Compressor Block

- Cast iron casters with high strength; The oil level indicator, the blowdown valve and the oil fill / drain plugs, which are easily accessible on the sump.

- Cooling finned cast iron cylinders and top heads help the system operate at lower temperatures.

- Specially designed steel cast crankshafts and counterweights with dynamic balancing and precise manufacturing processes ensure long service life.

- Special alloyed aluminum pistons and steel cast connecting rods suitable for Lloyd certification allow the compressor to operate even under extreme conditions, with less heat applied to the crankshaft as well as high heat transfer.

- Specially designed finger-type high-pressure suction-discharge valves made from stainless steel in grade 1 provide high airflow capacity while suction-discharge valves specially designed for high pressure conditions in stage 2 ensure airflow at maximum level, ensuring that the head cap temperature is at an optimal level .

- Compression and oil rings help to keep the airflow at maximum level and prevent oil passage.

Maın Motor and Drive System

- High efficiency IE2 efficiency class IP55 motors are used as standard in DKK series high pressure piston air compressors.

- The drive of the crankshaft is effected by a belt-pulley mechanism selected according to a certain transmission ratio between the compressor block and the main motor.

- The belts were selected for a working life of 25,000 hours.

- Specially designed fan-type cast iron pulleys dampen vibrations in the body by functioning as a flywheel as well as providing high volume airflow to cool the compressor block.

- Easy adjustable belt tension ensures efficient operation of the compressor at all times.

- Special no-load operating system extends the life of the electric motor and the compressor block.

Safety Systems

- Manual drain valve

- Checkvalve

- Belt-pulley order

- High pressure switchgear

- 1st and 2nd stage safety valves

- Output pressure manometer

- 1st stage pressure manometer

Standard Features

- Turkish and French Loydu type-approval certificates

- Piston compressor block

- 380V / 3phase / 50Hz IE2 efficiency class IP55 main motor

- Automatic evacuation system for unloading

- Belt-pulley mechanism driven system

- Special design fan type iron casting pulley

- Long life bearings

- Air cooled aftercooler

- Air intake filter and silencer

- Lubrication lubrication system

- Oil level indicator

- Factory filled oil

Options

- High pressure dryer

- High pressure air tank made of CE certified P265GH pressure vessel steel

- Motor drive system with star-delta connection

- Soft starter

- IE3 efficiency class main engine

- Other input voltage options except 380V / 3phase / 50Hz