TECHNICAL DATA

Our new model heat exchanger has easy assembly and disassembly feature. Aluminum fins allow efficient heat transfer and it has a design devoid of freezing problems at low temperatures.

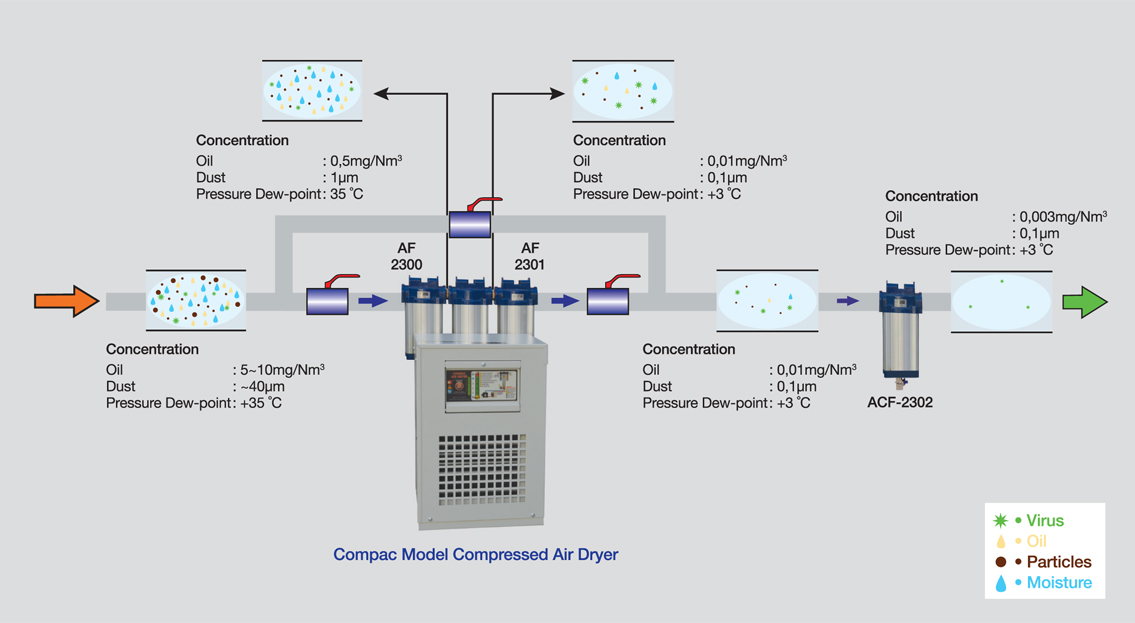

Compac-1 Series Compressed Air Dryers are designed for mold-injection industry, dry food pressing, hyperbaric oxygen treatment and similar fields in which outlet temperature must be the same with dew point value. It enables outlet temperature between +3 °C and the desired temperature.

Compac-2 Series Compressed Air Dryers are specifically designed for high inlet air temperatures. It enables stable dew point values with low pressure drops. Compac 2 Series Compressed Air Dryers work at max. 50°C ambient temperature and 100°C inlet air temperature with its special efficient heat exchanger design.

Compac-3 Series Compressed Air Dryers are manufactured for industries which require higher pressures, such as: PET inflation plants, starting diesel engines, high-voltage circuit breaks, test equipment, military facilities, marine-port applications, shipyards and fire departments. They work with high efficiency up till pressures of 45 bar.