Introduction video

What Are the Advantages of Durma AD-ES Electrical Press Brake?

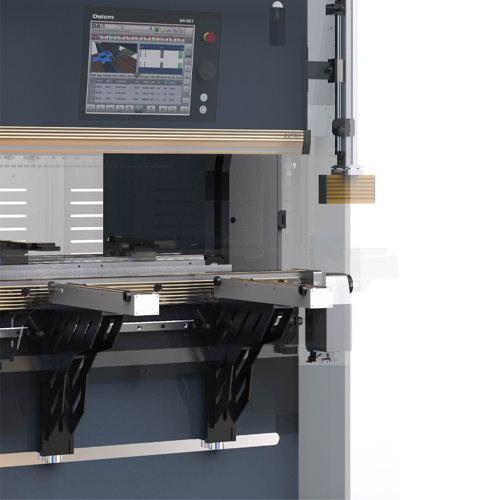

With an easy to use control unit, stable body structure, perfect design, low operating cost, different tool usage options, and maximum safety standards, Durma press brakes are the best in the world in their segment. Durma press brakes are fast, efficient and modern. Durma AD-ES Electrical Press Brakes are equipped with: Aluminum back gauge systems, front sheet supports, precise Hydraulic system, Durma licensed upper table sliding system, Euro type punch holders, high speed and stroke Y1-Y2 bending axis and CE level safety standards.

The Durma AD-ES Electrical Press Brake is designed to be efficient and eco-friendly. It will provide 40% Less energy consumption and 17% more productivity. The AD-ES Electrical Press Brake has perfect precision, high capacity elegant design. It is specifically manufactured to be low energy consumption. Its cutting-edge technology and equipment have a simpler drive group. Moreover, having less components allows easy and fast assembly. Its design is easy to use and easy to maintain. It has a hydraulic oil-free drive system.

Technology of Durma AD-ES Electrical Press Brake

- AD-ES Press Brakes are equipped with:

- Precision belt-pulley system,

- Upper table suitable for EURO / Wila type tools,

- Robust body structure with long life and high performance,

- Electric Panels creating a safer working environment,

- Servo motors providing high speed and high precision,

- Ball screw and nut connection providing excellent power and motion transmission,

- Roust back support system and rigid aluminum body AP1-AP2, system with high mobility and aluminum miter,

- CE Norm Safety Standards.