Introduction video

What are the Advantages of the Durma AD-EB Electrical Press Brake?

- Smart energy consumption with electrical servo system,

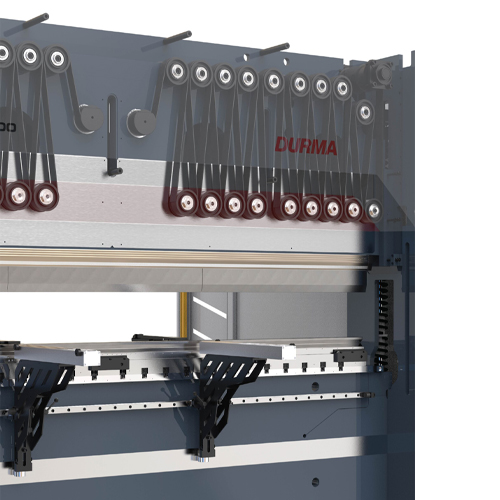

- Precision belt-pulley system,

- Correct bending at each point of the machine,

- No need for a crowning system, thanks to the slotted bottom table,

- Low maintenance cost.

The Technology of Durma AD-EB Electrical Press Brake

Durma AD-EB Press Brakes; thanks to their high-strength bearing pulley system, precision gear mechanism, reducer drive system and electric servo motors that do not require hydraulic oil, provide excellent results without the need for cambering on customer parts and saves energy for your company.